Kuti tiite mapurojekiti esimbi yehardware, mainjiniya edu anozonyatso sarudza maitiro ekuita zvigadzirwa zvakasiyana.

Iwo akajairika maitiro ekugadzirisa zvigadzirwa zve Hardware parizvino anosanganisira:

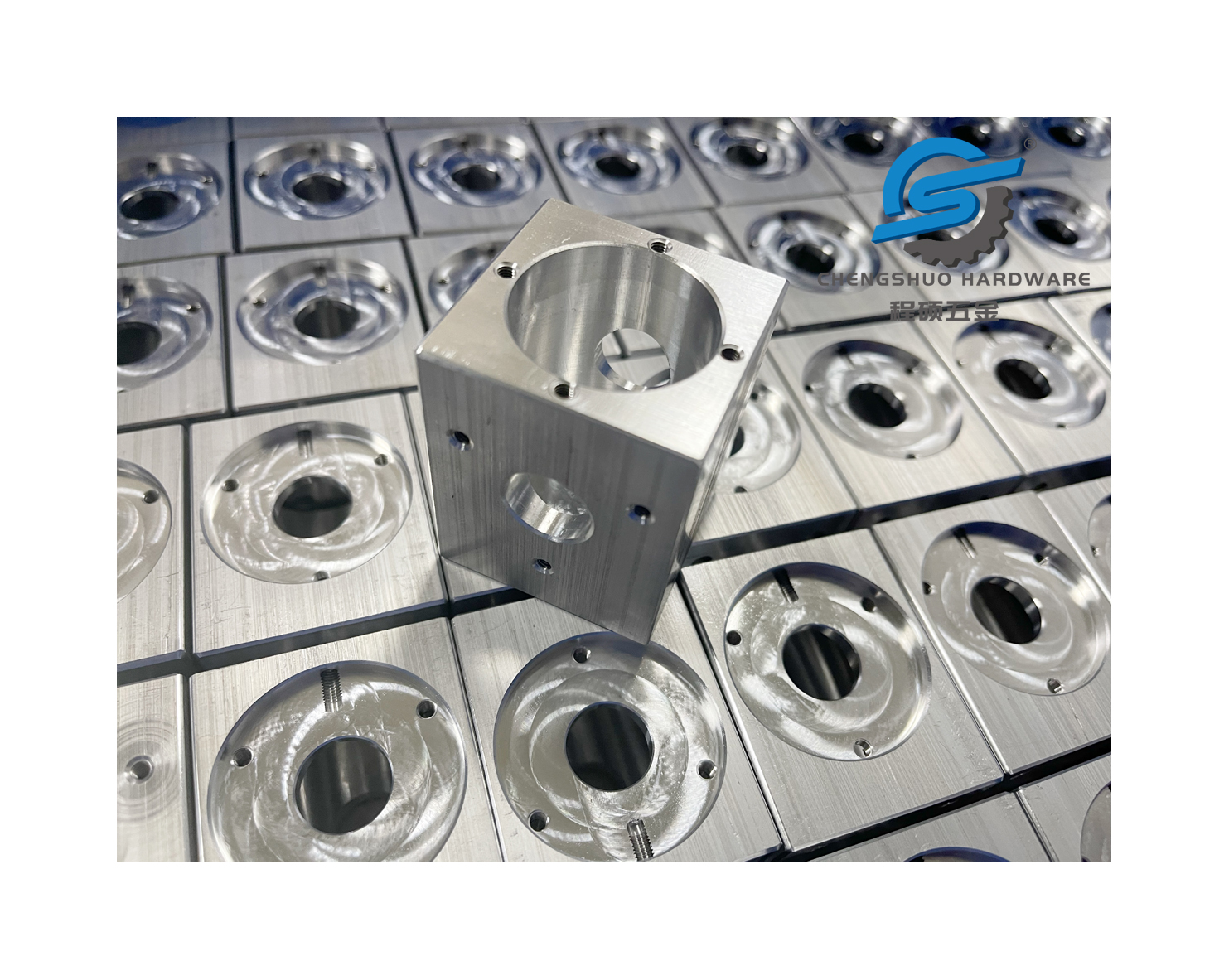

1. CNC machining

CNC kutendeuka, kugaya, kubaya, CNC cutting processing zvinoreva nzira yekucheka chidimbu chebasa kuita chimiro chinodiwa uye saizi kuburikidza nemudziyo wekucheka. Maitiro ekucheka akajairwa anosanganisira kutendeuka, kugaya, kuchera, nezvimwe.

Pakati pavo, kutendeuka ndiko kushandiswa kwemidziyo yekucheka pane lathe kugadzirisa zvidimbu zvebasa zvinotenderera, izvo zvinogona kuburitsa dhayamita dzakasiyana, kureba, uye maumbirwo shaft zvikamu;

Kugaya iko kushandiswa kwezvishandiso zvekucheka pamushini wekugaya kutenderedza nekufambisa zvimedu zvebasa, izvo zvinogona kuburitsa akasiyana siyana akafuratira maumbirwo uye convex concave nzvimbo dzezvikamu;

Kuchera ndiko kushandiswa kwezvishandiso zvekucheka pamushini wekuchera kuchera makomba muzvidimbu zvebasa, izvo zvinogona kuburitsa maburi emadhayamita akasiyana nekudzika.

Chengshuo yakashandisa yedu CNC machining centre, iyo inogona kupa imwechete-kumira masevhisi kune yakagadziridzwa yakakwirira-chaiyo zvigadzirwa zvine akasiyana mbishi zvinhu.

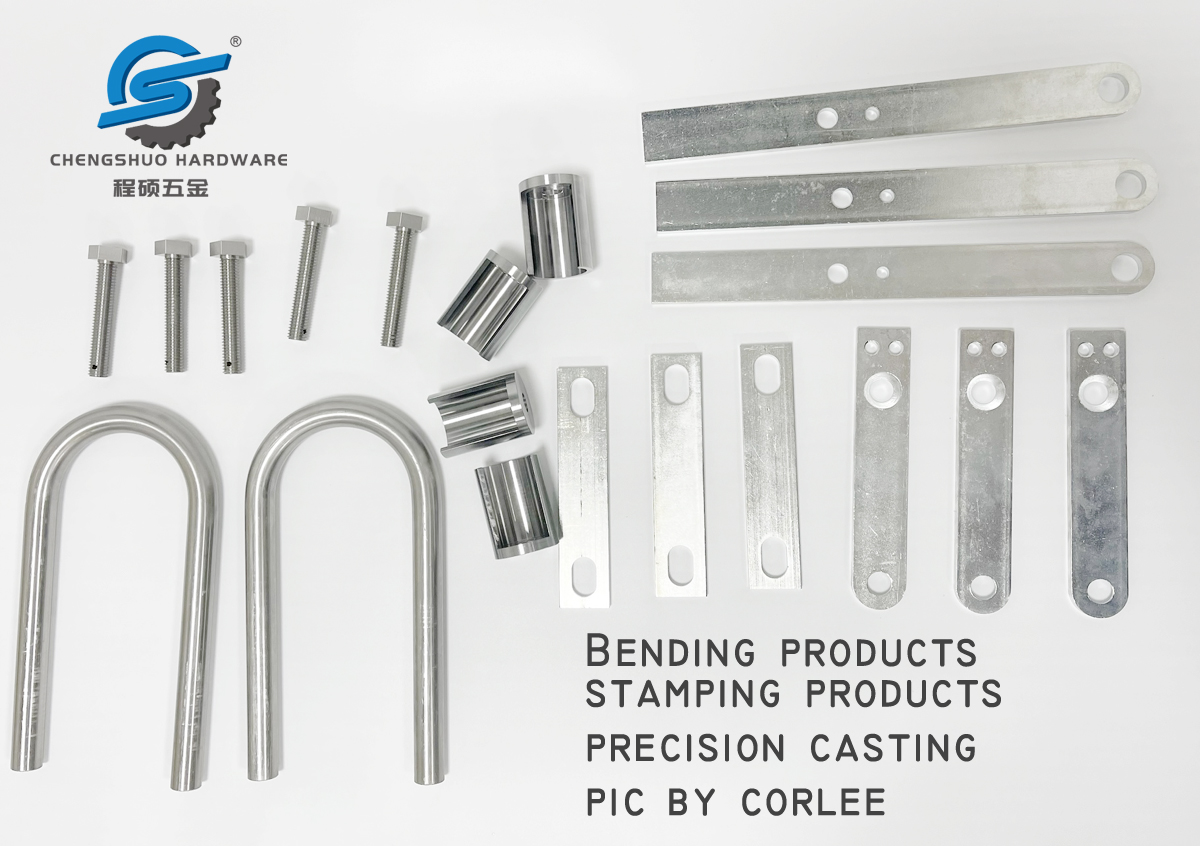

2. Stamping processing - Stamping centre

Stamping processing (stamping processing) zvinoreva nzira yekurovera simbi machira muchimiro chaidiwa kuburikidza nekukanda zviumbwa. Maitiro akajairika ekutsika anosanganisira kucheka, kubaya, kukotama, etc. Pakati pavo, kucheka ndiko kucheka simbi pepa maererano nehumwe saizi kuti uwane saizi inodiwa yezvikamu zvakatsetseka. Kurova ndiko kushandisa mold pamushini wekubaya kubaya simbi yesimbi, iyo inogona kuwana maumbirwo akasiyana uye saizi yemakomba; Kubhenda ndiko kushandiswa kwemuchina wekupeta kupeta masimbi, zvichikonzera maumbirwo akasiyana-siyana nemakona ezvikamu.

Stamping die ishongedzo yemidziyo inoshandiswa mukutonhora yekutsikirira kugadzira zvinhu (simbi kana isiri-simbi) kuita zvikamu (kana semi-yakapera zvigadzirwa), inonzi inotonhora stamping die (inowanzozivikanwa sekutonhora kutsika kufa)

Common classification ye stamping molds:

(1) Chiumbwa chimwe chete chiumbwa chinopedzisa kutsika kumwe chete muchikamu chimwe chemuchina.

(2) Iyo inoumbwa mold inongova nenzvimbo imwe chete yekushanda, uye mune imwe sitiroko yemuchina, iyo mold inopedzisa maviri kana anopfuura maitiro ekutsika panguva imwe chete pane imwechete yebasa.

(3) Progressive die (inozivikanwawo sekuenderera mberi kufa) ine maviri kana anopfuura masitesheni ekushanda munzira yekudyisa mbishi. Iyo mold inopedzisa maviri kana anopfuura ekutsika maitiro pane akasiyana masitesheni mune imwe sitiroko yemuchina.

(4) Iyo yekuchinjisa mold inosanganisa hunhu hweimwe process molds uye inofambira mberi mold. Nekushandisa robhoti yekufambisa ruoko system, chigadzirwa chinogona kukurumidza kuendeswa mukati me mold, ichivandudza zvakanyanya kugadzirwa, kudzikisa mutengo wekugadzira, kuchengetedza mutengo wezvinhu, uye kuona yakagadzikana uye yakavimbika mhando.

3. Welding processing

Welding processing inzira yekubatanidza simbi mbiri kana kupfuura kuburikidza nekudziya, kunyungudika, kana kudzvanywa. Kazhinji welding maitiro anosanganisira arc welding, fluorine arc welding, gasi welding, etc. Pakati pavo, arc welding inoshandisa kupisa kwearc inogadzirwa nemuchina wekugadzira kunyunguduka uye kubatanidza zvinhu zvesimbi pamwe chete; ammonia arc welding inoshandisa kupisa kunogadzirwa neammonia arc pasi pekuchengetedzwa kwegasi rinodzivirira kunyunguduka uye kubatanidza zvinhu zvesimbi pamwechete; gasi welding inoshandisa kupisa kwemurazvo kunokonzerwa nekupisa kwegasi kunyunguduka uye kubatanidza zvinhu zvesimbi pamwechete.

4. Bending processing - kukotama centre

Kupeta (Bending process) zvinoreva nzira yekupeta simbi kuita chimiro chaunoda kuburikidza nemuchina wekupeta. Kubhenda kwakajairika kunosanganisira V-kupeta, U-kupeta, Z-kupeta, etc. Pakati pawo, kupeta kwakafanana neV kunoreva kupeta simbi pane imwe kona kuti iite chimiro chakaita V; Kukotama kwakaita U-kureva kupeta bepa resimbi pane imwe kona kuita chimiro chakaita U; Z-kupeta inzira yekupeta simbi pepa pane imwe kona kuti iite Z-chimiro

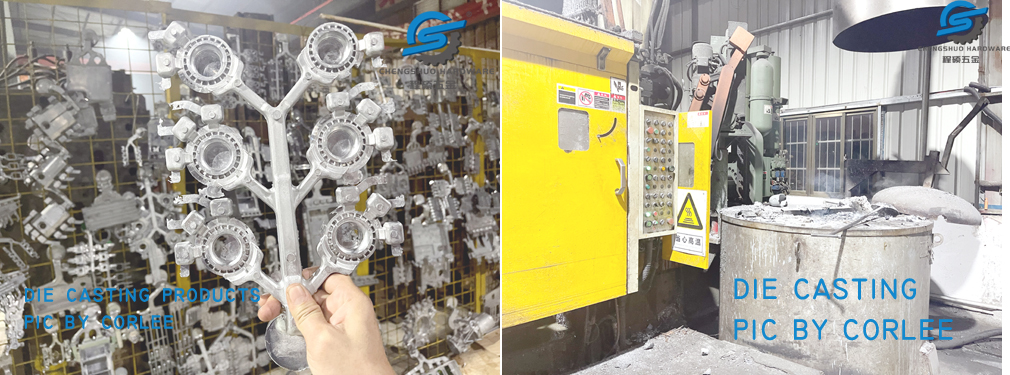

5. Die casting processing - Die casting centre

Kazhinji inoshandiswa kugadzira rough hardware zvigadzirwa. Die casting ndiyo chidimbu chepressure cast. Iyo inzira yekuzadza mhango yefa yekukanda mold ine mvura kana semi liquid simbi pakumanikidzwa kukuru uye nekukurumidza kusimba pasi pekumanikidzwa kuwana kukanda. Iyo die casting mold inoshandiswa inonzi die casting mold.

6. Wire cutting processing

Chengshuo Hardware ine yayo yekucheka waya michina. Mutsetse wekucheka chidimbu chekucheka mutsara, zvichireva nzira yekugadzirisa. Yakagadziridzwa pahwaro hwemagetsi ekuburitsa perforation uye kugadzira kugadzirisa. Iyo inzira yekugadzira inoshandisa tambo dzesimbi dzinofamba (molybdenum wire, copper wire, kana alloy wire) sewaya dze electrode, uye inogadzira tembiricha yakakwira kuburikidza nekuputika kwemagetsi kubuda pakati pewaya dzeelectrode uye workpiece, zvichiita kuti simbi inyunguduke kana kunyunguduka, ichigadzira. kucheka seams, uye nokudaro kucheka zvikamu.

Mushure mekugadziriswa kwakasiyana-siyana, chigadzirwa chinoitwa kwakasiyana-siyana kwepamusoro kurapwa.

Kurapa kwepamusoro kunoreva maitiro ekuchenesa pamusoro, kubvisa ngura, anti-corrosion, kupfapfaidza uye mamwe marapirwo emidziyo yehardware. Mishonga yakajairika yepasi inosanganisira pickling, electroplating, spraying, etc. Pakati pavo, kugeza asidi ndiko kushandiswa kwekugadzirisa acidic kusvibisa uye kuchenesa nzvimbo ye hardware components, kubvisa oxides uye tsvina pamusoro. Electroplating ndiko kushandiswa kwe electrolysis kuisa simbi ions pamusoro pezvinhu zve hardware kuti dzigadzire firimu rinodzivirira uye kuvandudza kusagadzikana kwavo kwekuora; Kupfapfaidza iko kushandiswa kwemidziyo yekupfapfaidza kupfapfaidza pendi zvakaenzana pamusoro pezvinhu zvehardware, kugadzira firimu rekudzivirira kuti riwedzere kunaka kwavo uye kuramba kwemamiriro ekunze.

Nguva yekutumira: Zvita-13-2023