Chengshuo ine milling composite machining centre uye ruzivo rwakakura

mukugadzira zvigadzirwa zvepamusoro zvendarira.

Kana iwe uchida kugadzirisa zvishandiso zvendarira, ndapota tumira dhizaini yedhizaini kufekitori yedu.Tichakupa mabasa ehunyanzvi.Chekutanga, mainjiniya edu eR&D achave nekunzwisisa kwakadzama kwenzvimbo yekushandiswa kweramangwana rezvigadzirwa zvendarira zvinodiwa kugadzira.

Tevere, cheki yakaomesesa yekuumbwa ichaitwa yakavakirwa pane dzakasiyana ndarira zvinhu. Mainjiniya edu eR&D uye mainjiniya epamusoro achasarudza mhando dzendarira dzakakodzera uye zvinhu zvinoenderana nemamiriro ekushandiswa kwechigadzirwa, chimiro chechigadzirwa, uye kugona kwekugadzirisa, uye kugadzira makodhi ehurongwa hwemachining.

Zvinhu zvendarira zvinowanzoshandiswa munzvimbo dzedu dzeCNC machining ndeaya anotevera:

1. Mhangura yakachena

Mhangura yakachena kazhinji yakapfava uye ductile, uye dilution giredhi yakachena mhangura ine zvidiki zveakasiyana alloying zvinhu. Naizvozvo, izvi zvinobatsira kushandura imwe kana mamwe ekutanga hunhu hwemhangura yakachena kuita zvinodiwa. Saizvozvo, kuwedzera mamwe alloying zvinhu kune yakachena mhangura kunogonawo kuwedzera kuoma kwayo.

Kuumbwa kwekutengeserana yakachena mhangura ine inenge 0.7% tsvina. Zvinoenderana nezvakasiyana zvemukati zvezvakawedzerwa zvinhu uye tsvina, yavo UNS nhamba iC10100 kusvika C13000.

Mhangura yakachena ndiyo inonyanya kukodzera pakugadzira midziyo yemagetsi, iyo inosanganisira waya uye injini. Mukuwedzera, rudzi urwu rwemhangura rwakakodzerwawo nemichina yeindasitiri yakadai sekupisa kupisa.

2. Electrolytic mhangura

Electrolytic mhangura inobva kune cathode mhangura, iyo inoreva mhangura yakanatswa ne electrolysis. Kazhinji kutaura, kuita uku kunosanganisira kubaya majekiseni emhangura mumushonga uye kushandisa simba remagetsi rakakwana kubatsira kuchenesa mhangura. Naizvozvo, kusachena kwehuwandu hwemhangura yakawanda ye electrolytic yakaderera pane yemamwe mamakisi emhangura.

Pakati pemhangura yose ye electrolytic, C11000 ndiyo inonyanya kushandiswa, ine tsvina yesimbi (kusanganisira sulfuri) kazhinji isingasviki zvikamu makumi mashanu pamamiriyoni. Mukuwedzera, ivo vanewo maitiro epamusoro, kusvika ku100% IACS (International Annealed Copper Standard).

Iyo yakanaka ductility inoita kuti ive yakakodzera kushandiswa kwemagetsi, kusanganisira mhepo, tambo, waya, uye busbar.

3. Oxygen isina mhangura

Kuenzaniswa nemamwe marudzi emhangura, mhangura isina oxygen ine inenge isina oxygen. Muzviitiko zvakawanda, anaerobic mhangura mamakisi anosanganisira akawanda epamusoro conductivity magetsi emhangura zvikamu. Zvisinei, C10100 uye C10200 ndiyo inonyanya kuzivikanwa.

C10100, inozivikanwawo seOxygen Free Electronic Copper (OFE), imhangura yakachena ine okisijeni inokwana inenge 0.0005%. Pamusoro pezvo, ndiyo zvakare inodhura zvakanyanya pakati peaya mamakisi emhangura. Mukuwedzera, C10200, inozivikanwawo seokisijeni isina mhangura (OF), ine okisijeni inokwana inenge 0.001% uye yakakwirira conductivity.

Izvi oksijeni zvemahara zvemhangura zvemhangura zvinogadzirwa uchishandisa yepamusoro-mhando cathode mhangura kuburikidza nekunyungudika induction. Munguva yekugadzira, cathode mhangura inonyungudika pasi pemamiriro asina oxidizing akafukidzwa negraphite bath. Oxygen yemahara mhangura ine yakakwirira conductivity uye inonyanya kukodzera kushandiswa mune yakakwira vacuum midziyo yemagetsi, kusanganisira emission chubhu uye girazi simbi zvisimbiso.

4. Zviri nyore kutema mhangura

Ichi chinyorwa chemhangura chinoumbwa nezvinhu zvakasiyana-siyana zvealloying. Zvinhu zvikuru zvinosanganisira nickel, tin, phosphorus, uye zinc. Kuvapo kwezvinhu izvi kunobatsira kuvandudza machining emhangura iyi.

Mukuwedzera, mahara ekucheka mhangura zvinhu zvinosanganisirawo alloys emhangura semhangura nendarira. Ndapota cherechedza pfungwa dzinotevera:

Bronze ialloy yemhangura, tin, uye phosphorus, inozivikanwa nekuoma kwayo uye simba rekuita;

Brass ialloy yemhangura uye zinc, ine yakanakisa machining uye corrosion resistance;

Zviri nyore kucheka zvinhu zvemhangura zvakakodzerwa kugadzirisa zvikamu zvakasiyana zvemhangura, zvinosanganisira michina yemagetsi, magiya, mabearings, mota dze hydraulic components, nezvimwe.

5. Customized ndarira profiles ane akakosha reshiyo

Customized processing yemhangura zvinhu zvinosangana nezvinodiwa nenyika dzakasiyana kana maindasitiri.

Semuenzaniso, bismuth brass isina lead-isina yakagadziridzwa neChengshuo yevatengi ndeye isina mutobvu uye iri nyore kucheka mhangura. Inogona kutemwa isina mutobvu, nekudaro ichisangana nezvinodiwa zvemachining uye kuwana nzvimbo inopenya ine kushivirira kwakanyanya. Inofanira kunge iri nyore kucheka uye isina burrs.

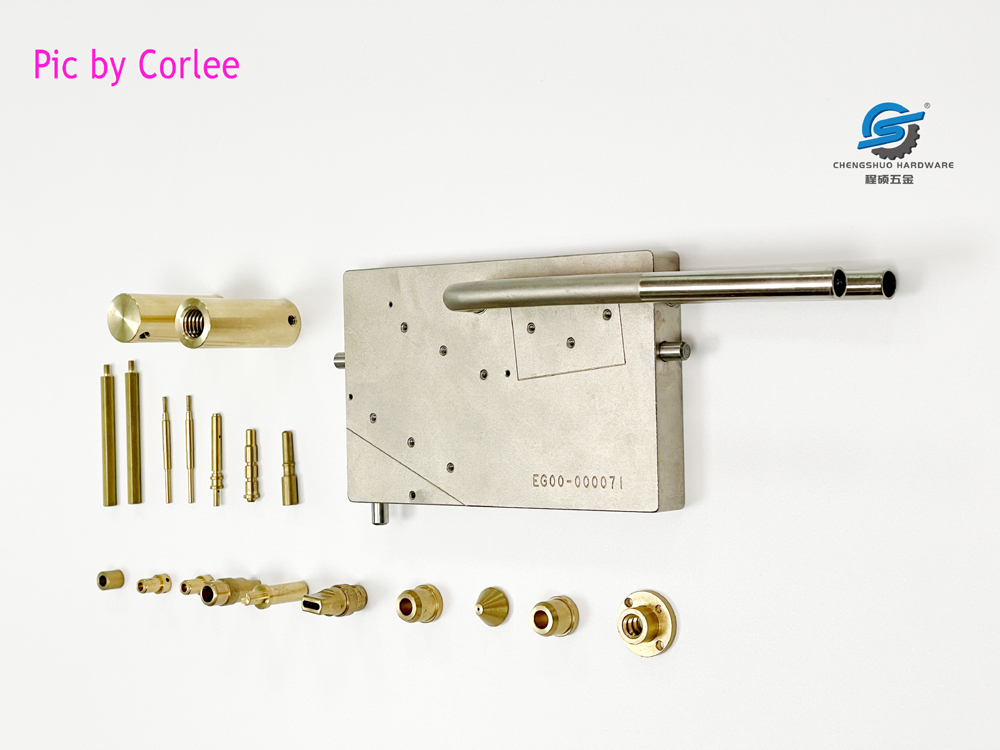

CNC machining tekinoroji yezvakajairwa mhangura zvigadzirwa

1. Mhangura milling processing

CNC milling ndeye otomatiki machining maitiro ayo anogona kudzora mafambiro uye chiyero chekudya chezvinotenderera zvekucheka maturusi. Kana CNC ichikuya mhangura, chishandiso chinotenderera uye chinofamba pamusoro pechinhu chemhangura. Zvadaro, iyo yakawandisa yemhangura inobviswa zvishoma nezvishoma kusvika yaita chimiro chinodiwa uye saizi.

CNC kugaya ndiyo nzira yakajairika mumhangura alloy machining, semhangura alloys ine yakanaka machining uye inogona kugadzirisa chaiyo uye yakaoma zvikamu. Double edged hard alloy end mills anowanzo shandiswa kukuya mhangura.

Cheng Shuo's mechanic inoshandisawo zvigadziriso zvekuzvigadzira kuti zviwane zvigadzirwa zvemhangura zvine maitiro akasiyana ekugadzira, uye ane ruzivo rwakapfuma mukuitwa kwezvakasiyana zvimiro zvakaita se grooves, maburi, uye flat contours.

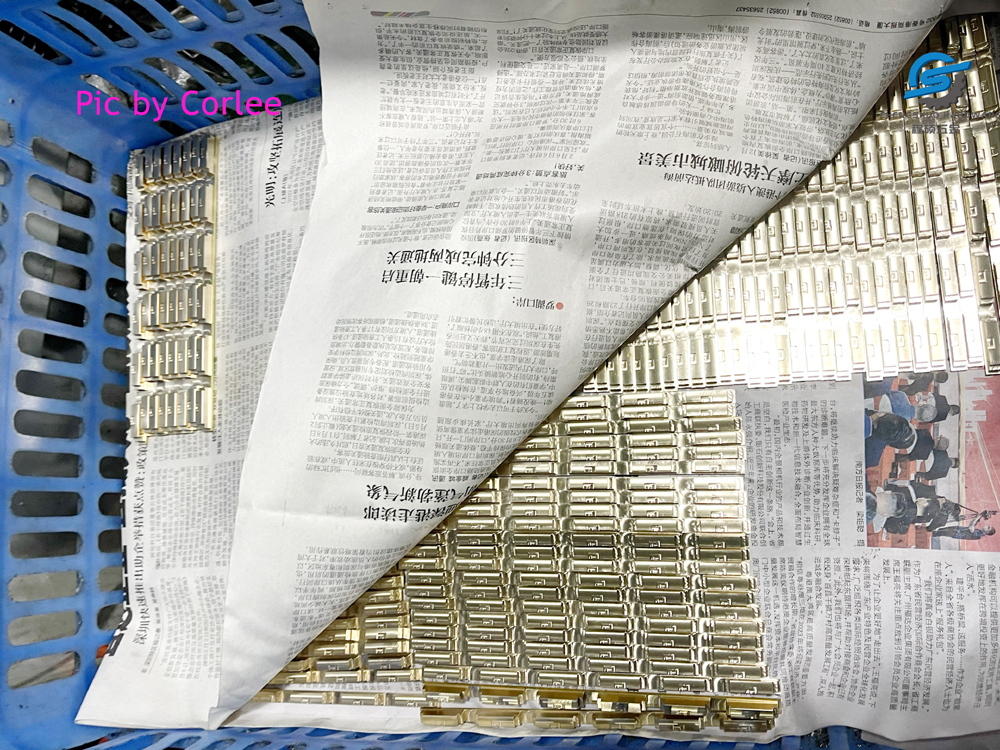

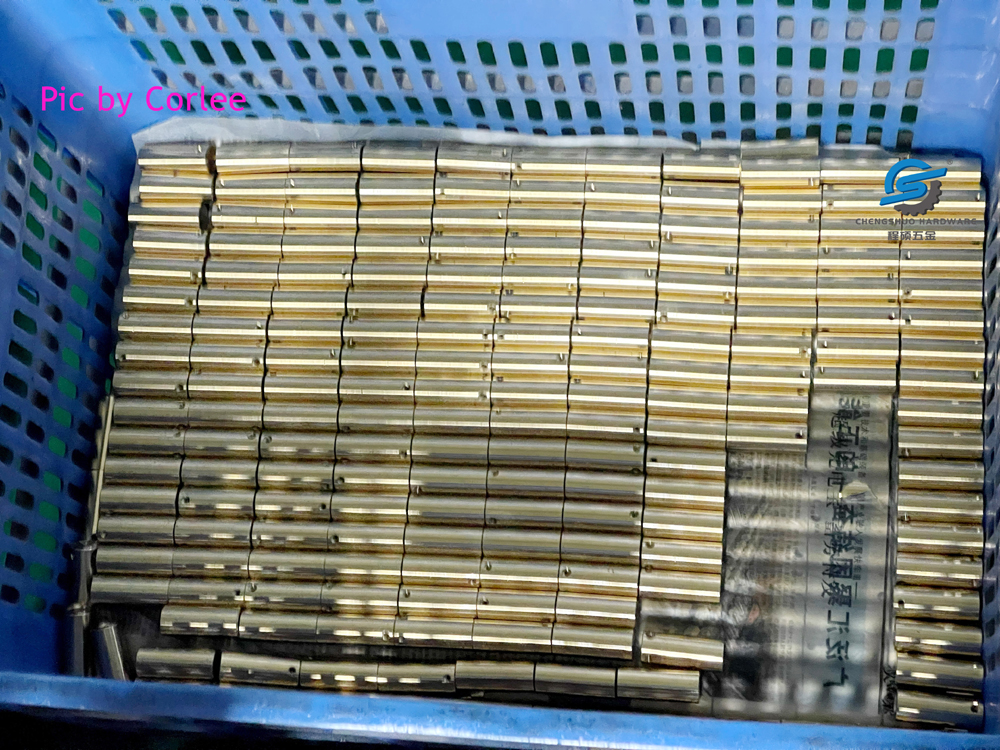

2. Kushandura kushandiswa kwezvigadzirwa zvemhangura

Chengshuo Hardware ndiye mukuru lathe mainjiniya ane ruzivo rwakapfuma mukutendeuka. Iyo mhangura yemhangura inogadziriswa munzvimbo yakagadziriswa yechishandiso chekucheka, uye mhangura workpiece inoshandurwa pane yakatarwa kumhanya. Nekubatsirwa kwekushandura mvura, cylindrical brass zvikamu zvinopedzwa.

Kutendeuka kwakakodzera kune akasiyana alloys emhangura uye anogona kukurumidza kugadzira yakakwirira-chaiyo mhangura zvikamu. Mukuwedzera, iyi nzira inewo mari-inoshanda. Naizvozvo, CNC inotenderedza mhangura inokodzera kugadzira akawanda emagetsi uye emuchina zvinhu, senge waya yekubatanidza, mavharuvhu, mabhasi, masingi ekupisa, nezvimwe.

Nguva yekutumira: Nov-29-2023